| Categories | Excavator Spare Parts |

|---|---|

| Brand Name: | Huilian |

| Model Number: | JHM516849 JHM516810 |

| Certification: | IOS9001 |

| Place of Origin: | China |

| MOQ: | 1PCS |

| Price: | Negotiable |

| Payment Terms: | T/T, L/C, MoneyGram |

| Supply Ability: | 1000 Pieces per Month |

| Delivery Time: | 1-7 work days |

| Packaging Details: | PP bag, Carton, Wooden cx, or as Required |

| Type: | Excavator Bearing |

| Product name: | Bearing |

| AppliCATEEEEEEion: | Excavator |

| Standard or nonstandard: | Standard |

| Warranty: | 3 months |

| Condition: | 100%New Excavator Bearing |

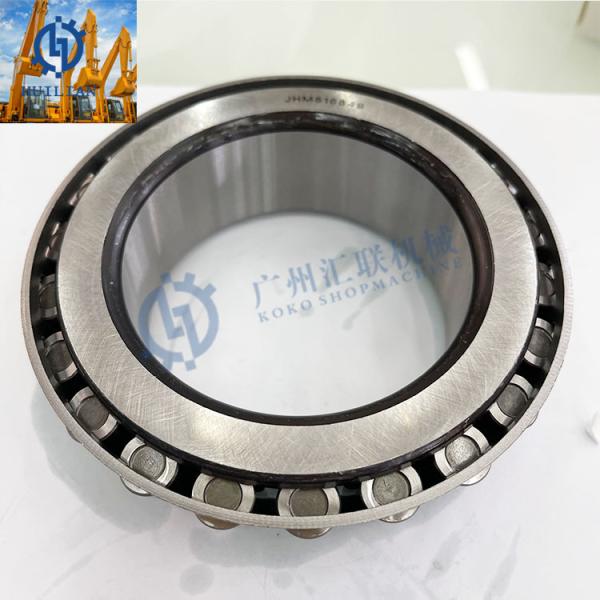

| keyword: | Tapered Roller Bearings |

| packing: | box |

Excavator Bearing JHM516849 JHM516810 Tapered Roller Bearings High Quality Factory Outlet Durability Hydraulic Pump Bearing

| Attribute | Value |

|---|---|

| Type | Excavator Bearing |

| Part number | JHM516849 JHM516810 |

| Application | Excavator |

| Standard or Nonstandard | Standard |

| Warranty | 3 months |

| Condition | 100% New |

| Packing | Box |

Excavator Model: All Excavator Models

Structure: Excavator Bearing

After Warranty Service: Online Support

Packaging: Wooden

1. Core moving Parts

Upper rotary platform (rotary system)

Application part: The section connecting the upper body (cab,

engine, counterweight) and the lower body (track chassis) of an

excavator.

The bearings used: Slewing Ring Bearing, which is a special type of

large rolling bearing.

Function: It enables the upper part of the excavator to rotate

continuously and infinitely at 360 degrees. This is the most

distinctive action of an excavator. The slewing bearing needs to

withstand huge axial forces, radial forces and overturning moments.

2. Boom, bucket arm and bucket (working device/boom/boom)

Application part: The connection hinge points between various

components.

The Bearings used: mainly heavy-duty radial Spherical Plain

Bearings and Tapered Roller Bearings.

Function: It can withstand huge digging resistance and impact

loads, allowing the boom to rise and fall, the bucket to extend and

retract, and the bucket to rotate. These bearings usually operate

in harsh environments such as soil and sand, and have extremely

high requirements for sealing performance and wear resistance.

3. Walking system (track chassis)

Application parts: Track idler wheels, guide wheels, drive wheels

and idler wheels.

Bearings used: tapered roller bearings and Deep Groove Ball

Bearings (Bearings).

Function: To support the entire weight of the excavator and achieve

the walking function. They need to withstand extremely strong

impacts and vibrations, as well as severe pollution from muddy

water and crushed stones.

4. Other important parts Engine

Like all car engines, high-precision bearings such as deep groove

ball bearings and needle roller bearings are required for the

internal crankshaft, camshaft, gearbox, etc., to ensure smooth and

high-speed operation.

5. Hydraulic system

Application parts: The interiors of hydraulic pumps and hydraulic

motors.

Bearings used: Special axial piston pump bearings, etc.

Function: The hydraulic system is the "muscle" of an excavator.

These bearings are used to support the rotating parts inside the

pump and motor, withstanding complex loads under high speed and

high pressure.

6. Cab control mechanism

The connection points of the joystick will also use some small

spherical plain bearings or needle roller bearings to ensure smooth

and flexible operation.

Applicable Industries

Construction, mining, road and highway construction, building demolition, foundation construction, tunnel work, stone and rock breaking, ditching, and special sites.

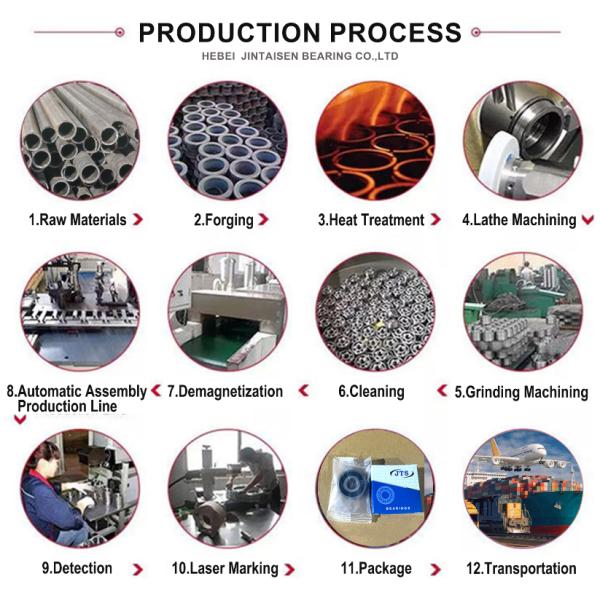

Guangzhou Huilian Machinery Equipment Co., Ltd.established in 2 0 1 1, located in Guangzhou city with convenient

transportation access. We has a registered capital of 4 million R M

B and occupies an area of 20, 000 square meters. The company has an

annual production capacity of 3 million sets. Our main products

include deep groove ball bearings, tapered roller bearings,

spherical roller bearings, pillow block bearings, and cylindrical

roller bearings.

We own the independent brand J T S and also provide O E M services

based on customer requirements. Our production workshop is equipped

with 60 automated machine tools to ensure stable output. The

assembly workshop is fitted with advanced ultrasonic cleaning

equipment, automatic assembly machines, and automated packaging

lines. A variety of inspection equipment, such as profilometers,

vibration testers, clearance testers, and microscopes, ensures the

quality of every product. Our workers, with 14 years of experience,

operate under a strict and complete assembly line process to

guarantee high- quality production.

Our products are widely applied in automobiles, electric motors,

water pumps, agricultural machinery, gearboxes, mining machinery,

sports equipment, construction, and mining equipment. The company

holds independent import and export rights, and all products are I

S O 9 0 0 1 certified. We have also obtained a high- tech

enterprise certificate. Our foreign trade team has 10 years of

experience and has successfully cooperated with customers from many

countries. Our products are exported to the United States, Brazil,

Chile, Indonesia, Malaysia, Iran, Nigeria, Kenya, South Africa,

Slovenia, and more. We welcome customers from at home and abroad to

establish cooperation and create a bright future with us together.

FAQ

1. Q: Are you a trading company or manufacturer?

A: We are a certified bearing manufacturer with 15+ years of

OEM/ODM experience.

2. Q: How long is your delivery time?

A: In-stock items: 2-5 working days (EXW/FOB NANSHA Port)

Custom orders: 15-30 days (Subject to technical complexity)

3. Q: Can I get free samples for testing?

A: Standard samples (non-high-value items) are available. Sample

fees are deductible from bulk orders.

4. Q: What is the MOQ of your products?

A:Standard bearings: ≥1 unit (Flexible according to demand)

Customized solutions: ≥500 units

5. Q: How do you ensure product quality?

A: Products undergo 3-stage inspection:

Raw material certification (GCr15 steel, HRC 60-64 hardness)

100% dimensional testing during production

Final QC approval by professional team

6. Q: What are your payment terms?

A:Orders ≤1,000 USD: 100% advance payment

Orders >1,000 USD: 30% T/T deposit, 70% balance before shipment

L/C accepted for orders >50,000 USD

7. Q: Can you design bearings for special applications?

A: Yes! We provide:

Customized rings/retainers design

Special lubricants (Grease/Oil/Dry-film)

IP6K9K dustproof & waterproof solutions

Technical drawings or samples required

8. Q: What certifications do you have?

A: ISO 9001:2015

9. Q: What industries do your bearings serve?

A: Automotive, robotics, mining equipment, wind turbines, and

agricultural machinery.

|

Quality Excavator Attachment 20t 21t 22t 23t 24t 25t 26t 27t 28t 29t 30t 31t 32t 33t R200-5 R200-5D R210 Hydraulic Eagle Shear wholesale

Quality Excavator Attachment 20t 21t 22t 23t 24t 25t 26t 27t 28t 29t 30t 31t 32t 33t R200-5 R200-5D R210 Hydraulic Eagle Shear wholesale

Quality High Strength Subway Rock Digging Drilling Bucket For 20Ton 30ton Steel Mini Crawler Excavator With 1 Year Warranty wholesale

Quality High Strength Subway Rock Digging Drilling Bucket For 20Ton 30ton Steel Mini Crawler Excavator With 1 Year Warranty wholesale

Quality Excavator Spare Parts 2401-9225 2401-9158 2401-9303 main pump hydraulic pump for doosan SOLAR 220LC SOLAR 220LC-6 wholesale

Quality Excavator Spare Parts 2401-9225 2401-9158 2401-9303 main pump hydraulic pump for doosan SOLAR 220LC SOLAR 220LC-6 wholesale